- Garkheda Road , Aurangabad MS - 431005

- Time : Monday - Sat 09am - 6pm

- sushil@a2f-filters.com

- a2f Filters

DUST COLLECTOR

Our range of equipment & systems are designed with best of its quality & performance & are accepted by various Govt. & Private sector establishments across the nation.

- Home

- A2F Filter

- A2F® MAKE DUST COLLECTOR

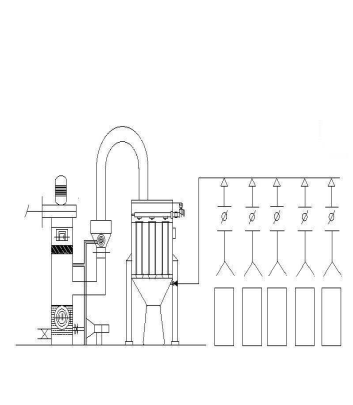

DUST COLLECTOR

A2F® MAKE DUST COLLECTOR

A2F® offers widest range of Laminar Air Flow Equipments, Dust Collectors, Filter Cleaning Booths , Dedusting Booths & Systems for the Application in the field of Scientific & Industrial Research, Micro Biology & Tissue Culture, Hospitals & Medical Education, Drugs & Pharmaceutical Industries, Electronics & Space Applications, etc. Our range of equipment & systems are designed with best of its quality & performance & are accepted by various Govt. & Private sector establishments across the nation.

Particular Advantages:

• Dust collector are designed to handle heavy dust loads and consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system.

• Pulse jet type reverse air cleaning.

• High Collection efficiency (Coarse Dust)

• Adequate to high dust concentration.

• For high gyroscopic powders scrubbers can also be incorporated Models available in 18 gauge (1.2 mm) stainless steel 304.

• Dust Collector Unit is formed by a stainless steel as well as MS Powder Coated.

• Filter Housing: Dust collector system will incorporate filter cartridges encased in an MS/SS casing. The system will comprise a centrifugal fan with motor and starter , motor will be non flame proof and fittings will also non flame proof . The suction spreads into the bottom of the dust collector, and Cyclone separation takes place. The dust-laden air further hits the external surface of the cartridge, and clean air will enter from inside of the cartridge into the fan and then it shall be discharged into the atmosphere through the outlet of the fan. Every two cartridge will be connected through solenoid valve , digital micro controlled timer to compressed air 4 to 5 kg/cm2 pressure and the air will be passed into the air receiver tank from where it shall be delivered into each cartridge by pipelines & Venturi . The time for cleaning will be fully automatic operation can be manually programmable ; compressed air to be blown through the injector and stretches the filter cartridge abruptly to drop the dust into the hopper conical bottom .

• Centrifugal Suction Blower and Silencer: The centrifugal Blower is made up of CS with type backward inclined.

• Bottom Hopper: The Bottom Hopper is made up of Stainless steel/ MS. As the air enters the hopper, velocity suddenly drops due to increase in cross sectional area and falls below transport velocity, hence most of the particles are collected in the hopper.

Over the past 20 years, there has been an explosion of technology and information. The speed, volume and complexity of work have increased dramatically in the 21st century, and at a2f each one is prepared to work in this fast-paced and demanding environment. Most of our established habits for being productive were created and popularized nearly 20 years ago-and leave us prepared for the speed,volume and complexity of our work and our lives. When you turn to a2f for filtration solutions , you get more than just high -performance products. Sure, our innovative technologies , help to serve you with speed , volume , complexity and anything in filtration is available out of your demand . We combine global resources, unmatched technical expertise and a commitment to responding to your unique needs - making us the single-source supplier for any filtration, certification & testing application. Call us and see why industries prefer a2f products. Finally it' s what you don 't see that makes all the difference. We request you please guide us so that we may register our company with your organization . Awaiting for your reference in purchase for interaction . We look forward to be of service to you with best regards all the time we remain.

Application :

• Pharma floating powder collection

• Cement powder application

•Grinding powder in Engineering

• Powder Coating booths and Systems

• Foundry & Casting units

• Wooden furniture units

• Chemicals , API units, and Bulk Drugs

• Filters : PTFE Laminated Spun Bonded Polyester

1micron Cartridge Filter.

• Capacity : 500 CFM / 1000 CFM upto 50000cfm

• Blowers (Centrifugal) : Induction Run Non Flame Proof

Motor/ Flame Proof Energy efficient level 1 motors

• Filter Condition : Solenoid Valve with pulse jet

Accessories :

Dust Cartridge Filter, Optional : Plenum with 1 micron and

0.3 micron HEPA filters having Magnehelic gauge

Our Products

- AIR SHOWERS

- DUST COLLECTORS

- DISPENSING SAMPLKNG BOOTH

- DEDUSTING BOOTH

- FILTER CLEANING BOOTH

- HANGING LAMINAR

- LAMIANR AIR FLOW STATION

- PASS BOX STATIC & DYNAMIC

- GARMENT CUBICAL DYNAMIC

- AIR CURTAINS

- RISER FILTER WITH PERFORATED

- SHEET & MAGNETIC LATCHES

- SCRUBBER & EXTRACTORS

- BIO HAZARD CABINET

- SANITARY HOUSING

- MULTI CANDLE HOUSINGS

- FUME HOOD FOR QC

- IPC CONTAINERS

- TERMINAL FILTER GRILL WITH

- RETURN RISERS

- HEPA BOX

- CAPSULE GRILLS

- FAN FILTER UNIT (FFU)

- DIFFUSER

- DAMPERS GRILLS

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us