- Garkheda Road , Aurangabad MS - 431005

- Time : Monday - Sat 09am - 6pm

- sushil@a2f-filters.com

- a2f Filters

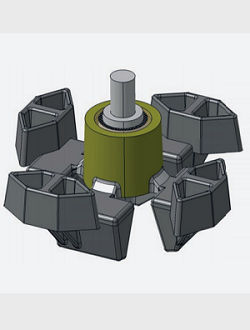

FILTER Riser

A2F® MAKE FILTER Riser

During the casting process, FILTER-Risers can be used to

cover the essential tasks of filtering and feeding the casting. Here, a combination of an insulating or exothermicinsulating riser body is made with a ceramic foam filter

that allows the foundry to pour the metal directly into the

casting.

Due to the flexibility of the system, FILTER-Risers can be

used in steel, iron and nonferrous castings as well as in all

common molding processes (vertical/horizontal/machine

and hand molding). The filter used must be adjusted to

suit the casting metal and the desired flow rate.

In order to further reduce cleaning costs, the FILTERRisers can be equipped with breaker cores. The riser neck

dimensions depend on the riser modulus and can

be adjusted to the individual application case.

Our FILTER-Risers are manufactured using inorganic riser

materials. There these are almost odor- and emissionfree in the manufacturing process of our customers.

Product advantages

• Increased yield• Reduced space requirement for the casting system leads to more efficient usage of the pattern, or a reduction of the molding box size

• Reliable feeding

• Reduction in cleaning costs

• Improved cast surface

• Inorganically bound feeder material – low odor and emission

Over the past 20 years, there has been an explosion of technology and information. The speed, volume and complexity of work have increased dramatically in the 21st century, and at a2f each one is prepared to work in this fast-paced and demanding environment. Most of our established habits for being productive were created and popularized nearly 20 years ago-and leave us prepared for the speed,volume and complexity of our work and our lives. When you turn to a2f for filtration solutions , you get more than just high -performance products. Sure, our innovative technologies , help to serve you with speed , volume , complexity and anything in filtration is available out of your demand . We combine global resources, unmatched technical expertise and a commitment to responding to your unique needs - making us the single-source supplier for any filtration, certification & testing application. Call us and see why industries prefer a2f products. Finally it' s what you don 't see that makes all the difference. We request you please guide us so that we may register our company with your organization . Awaiting for your reference in purchase for interaction . We look forward to be of service to you with best regards all the time we remain.

FILTER Riser

Particularly when casting with vertically split molds, the foundry desires an efficient pattern design and thus a space-saving pouring and riser system to guarantee efficient production. In this case, the positioning of FILTER-Risers with other elements can be carried out using an automated core setter operating in the machine cycle. The FS series has been developed to ensure reliable positioning of the riser feeders in a vertically split mold. This has the reverse taper shaped FILTER-Risers on a rectangular base, which ensure a precise fit in the mold

The pattern usage can be made more efficient by replacing a conventional casting system by a casting system with a FILTER-Riser. This results in a more economical sand-iron ratio, a reduction in recycled material, and an improved feed.

Our Products

- AIR SHOWERS

- DUST COLLECTORS

- DISPENSING SAMPLKNG BOOTH

- DEDUSTING BOOTH

- FILTER CLEANING BOOTH

- HANGING LAMINAR

- LAMIANR AIR FLOW STATION

- PASS BOX STATIC & DYNAMIC

- GARMENT CUBICAL DYNAMIC

- AIR CURTAINS

- RISER FILTER WITH PERFORATED

- SHEET & MAGNETIC LATCHES

- SCRUBBER & EXTRACTORS

- BIO HAZARD CABINET

- SANITARY HOUSING

- MULTI CANDLE HOUSINGS

- FUME HOOD FOR QC

- IPC CONTAINERS

- TERMINAL FILTER GRILL WITH

- RETURN RISERS

- HEPA BOX

- CAPSULE GRILLS

- FAN FILTER UNIT (FFU)

- DIFFUSER

- DAMPERS GRILLS

Quick contact

Get Solution

Organically grow the holistic world view of disruptive innovation via workplace diversity

Contact Us